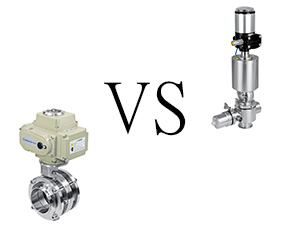

The optimal distance between the motor and the frequency converter

Permissible Cable Length Between Frequency Converter and MotorBecause the voltage waveform output by the frequency converter is similar to a sine wave, but not a true sine wave, it contains a large nu