With the development of human social productive forces, the development of regulating valves has gone through a long period of time. Nowadays, regulating valves play a very important role in the automatic control of modern factories, and today's pneumatic regulating valves have been used in electric power, petroleum, metallurgy, It is one of the industrial process control instruments widely used in chemical and other industrial enterprises. Below I will explain to you in detail the relevant content of the pneumatic control valve.

Pneumatic control valve is to use compressed air as the power source, the cylinder as the actuator, and with the help of electrical valve positioner, converter, solenoid valve, retaining valve and other accessories to drive the valve, to achieve switching or proportional adjustment, receiving industrial The control signal of the automatic control system is used to adjust the pipeline medium: flow, pressure, temperature and other process parameters. Pneumatic control valve is characterized by simple control, fast response, and intrinsic safety, without the need for additional explosion-proof measures. Pneumatic regulating valve is usually a combination instrument formed by connecting the pneumatic actuator and regulating valve after installation and debugging.

What is a Pneumatic Control Valve?

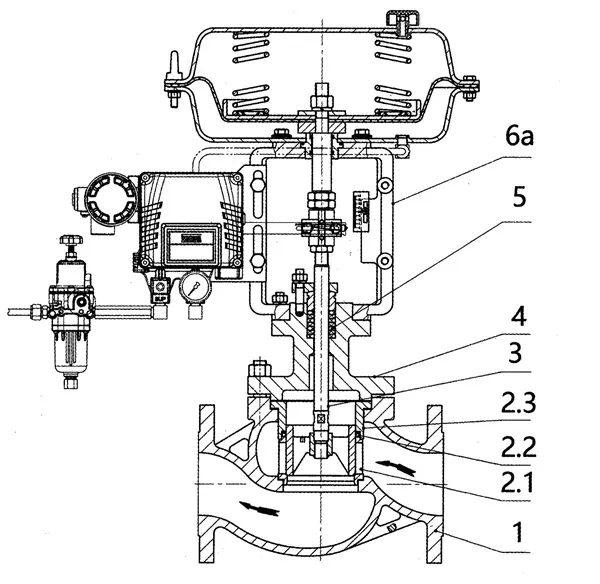

A pneumatic control valve is a mechanical device that uses compressed air to regulate the flow of liquids, gases, or slurries within a system. Unlike manual valves, these are automated and respond to signals from controllers, adjusting their position to maintain desired process conditions. Key components include:

-

Actuator: Converts air pressure into mechanical motion.

-

Valve Body: Houses the mechanism (e.g., globe, butterfly, or ball) that modulates flow.

-

Positioner: Ensures the valve opens or closes precisely as commanded.

The structure and working principle of pneumatic control valve

The action of the pneumatic control valve is divided into two types: air-open type and air-close type. The air-to-open type means that when the air pressure on the membrane head increases, the valve moves in the direction of increasing the opening degree. When the upper limit of the input air pressure is reached, the valve is in a fully open state. Conversely, when the air pressure decreases, the valve moves in the closing direction, and when no air is input, the valve is fully closed. Therefore, sometimes the air-opening valve is also called the fault-closing type. The action direction of the air-close type is just opposite to that of the air-open type. When the air pressure increases, the valve moves to the closing direction; when the air pressure decreases or does not, the valve moves to the opening direction or fully opens. It is sometimes called fail-open type

Where Are They Used?

Pneumatic control valves thrive in industries demanding safety and precision:

-

Oil & Gas: Managing pipeline pressures and hazardous fluid flows.

-

Pharmaceuticals: Ensuring sterile, precise dosing in production.

-

Food & Beverage: Regulating temperatures and flow rates in processing lines.

-

Water Treatment: Controlling chemical injection and filtration systems.

Their explosion-proof design (no sparks) makes them safer than electric alternatives in flammable environments.

Advantages Over Other Valve Types

-

Speed & Responsiveness: Compressed air enables faster actuation than hydraulic or electric systems.

-

Durability: Minimal moving parts reduce wear and tear.

-

Safety: No risk of ignition in volatile settings.

-

Cost-Effectiveness: Lower energy consumption and maintenance costs.

Maintenance Tips for Longevity

To maximize valve lifespan:

-

Use clean, dry air to prevent corrosion.

-

Regularly inspect seals and diaphragms for wear.

-

Calibrate positioners annually to ensure accuracy.

-

Lubricate moving parts as per manufacturer guidelines.

The Future of Pneumatic Control Valves

As Industry 4.0 reshapes automation, smart pneumatic valves are emerging. Integrated with IoT sensors, these valves offer predictive maintenance alerts, remote monitoring, and AI-driven optimization. Yet, their core principle—harnessing air pressure for precise control—remains timeless.

Conclusion

From regulating steam in power plants to dosing ingredients in a soda factory, pneumatic control valves are the invisible force behind industrial efficiency. Their blend of simplicity, reliability, and adaptability ensures they’ll remain a cornerstone of automation for decades to come. Next time you see a factory humming with flawless precision, remember: it’s the pneumatic control valves working tirelessly behind the scenes.