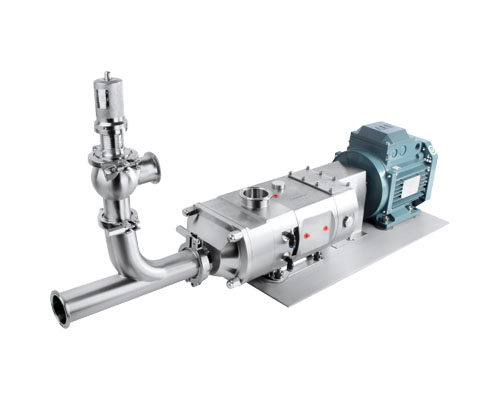

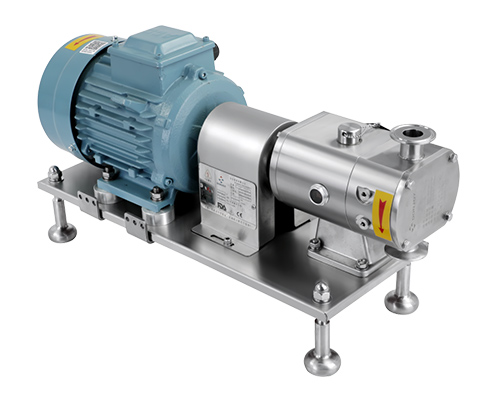

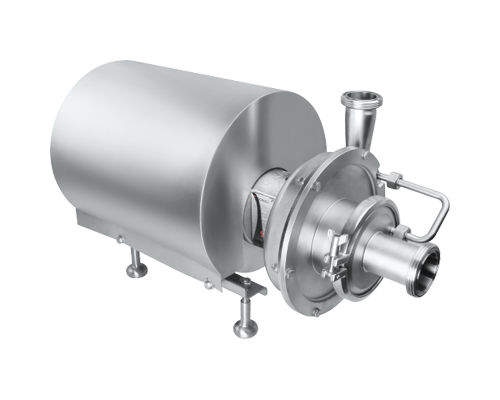

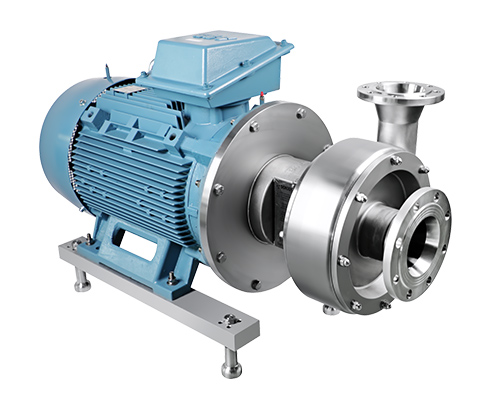

Twin-screw pump has self-priming ability and can transport various complex conditions such as solid particles, gas-liquid mixture, high viscosity, low viscosity and material transportation and extraction; it not only used for material extraction and Conveying, also applicable to CIP and SIP systems, can reduce pipeline, valve control, CIP dedicated pumps, Not only improve efficiency, but also reduces costs. The pump also has the performance that other volumetric pumps do not have, such as no pulse phenomenon, no damage to particles, high pressure, speed range and large flow range.

Max flow: 110m3/h

Max Particles: 23mm

Max pressure: 20 bar

Speed range: 10-3500 R.P.M

Working temperature (Max Temperature): -40 ° C to 150 ° C

Surface treatment: Ra≤0.6μm; EP=Ra0.4μm

Material: 100% stainless steel, medium contact part 316L.

Certification: 3-A-02-11 No.1759; FDA 177.2600; CE-MD/06-42 No .705201402401-00