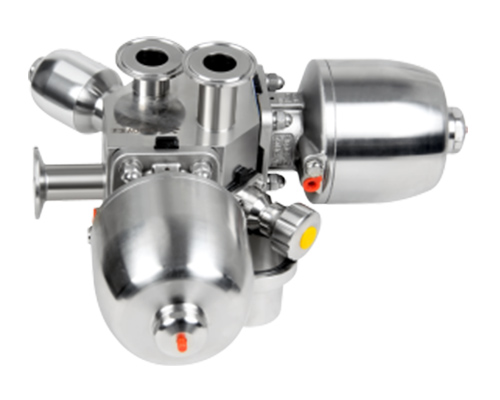

The valve mainly solves problem that cleaning ball long-term bubbles in the medium of the dead leg so that easy to produce bacteria to pollute media. Cleaning drain valve begins cleaning when it opens. It prevents cleaning ball and from medium to avoid the dead angle.

Cleaning drain valve is designed for pipeline and tank cleaning equipment online cleaning line.

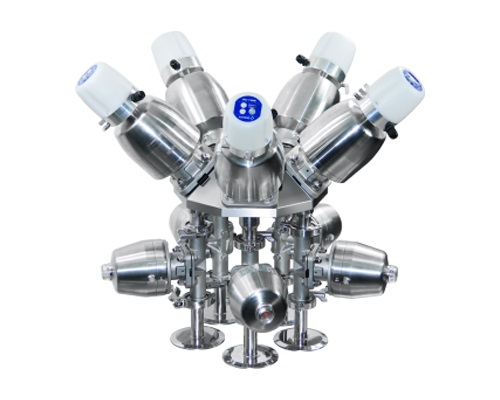

●Size:DN25/1" to DN100/4"

●Temperature:130℃

●Pressure:10bar

●Air supply:4-7bar

●Material:ASTM 304/1.4301,316L/1.4404

●Gaskets:EPDM、FPM、HNBR,FDA177.2600

●inner surface treatment:Ra<0.8μm

●Surface treatment: sand blasting, polishing

●Configuration options: position sensor, control unit

●Certificate:3-A-53-06,PED/97/23/EC,FDA177.2600