Advantages of Jet-Type Mixproof Valves:

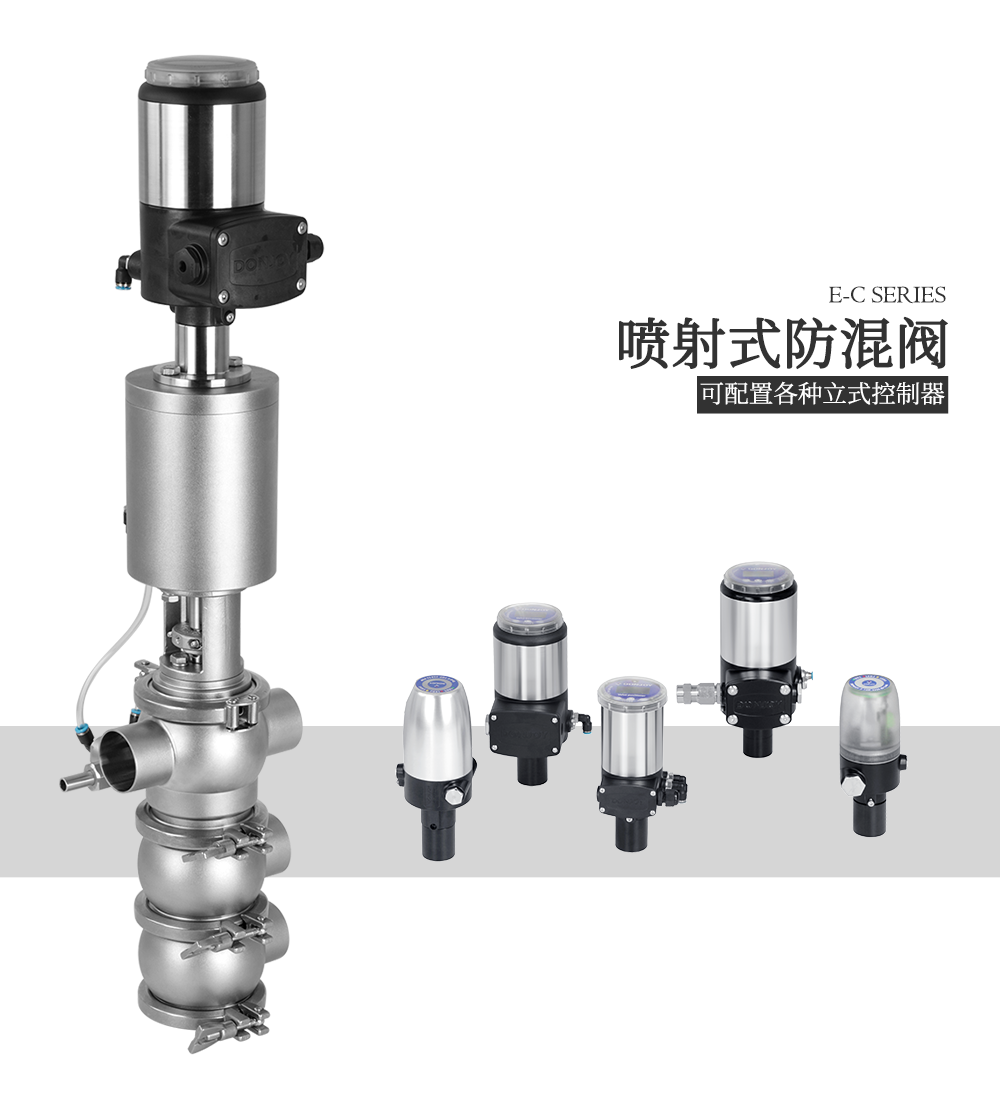

Jet-Type Mixproof Valves, with their unique structural design and advanced operating principles, offer unparalleled advantages in mixproof performance. Whether it's the precise stem movement and sealing design of the E-C Series mixproof valves or the extensive pipeline flow control capabilities of the two- and three-body mixproof valves, they fundamentally eliminate the risk of mixing between different fluids. In the food and beverage industry, they ensure that every drop of juice and every portion of syrup is precisely blended according to the recipe ratio, avoiding uneven mixing of ingredients that can compromise product taste and quality. In the pharmaceutical industry, they provide a solid line of defense for drug safety, ensuring the strict separation of each active ingredient and excipient to prevent cross-contamination, ensuring drug efficacy and patient safety.

Wide Range of Applications:

Jet-type mixproof valves are highly adaptable, operating stably in a variety of complex industrial environments to meet the diverse needs of various industries. From daily consumer goods industries like food, beverages, and dairy products, to pharmaceuticals, bioengineering, and fine chemicals with stringent hygiene and quality requirements, to large-scale industrial projects like oil, gas, and water treatment, jet-type mixproof valves find application everywhere. In food processing, they flexibly control the mixing and delivery of raw materials according to the production process of different products. In pharmaceutical production, they strictly adhere to GMP standards to ensure sterility and contamination-free drug production. In the chemical industry, they withstand harsh operating conditions such as high temperature, high pressure, and severe corrosion, ensuring safe and stable production.

In actual use, jet-type mixproof valves are also very easy to maintain. Their simple and rational structural design, with clear connections between components, facilitates easy disassembly and installation. Standardized designs are used for vulnerable parts such as seals and valve stems, making them easy to replace. Furthermore, by integrating with a CIP system, the valves can be operated in situ.