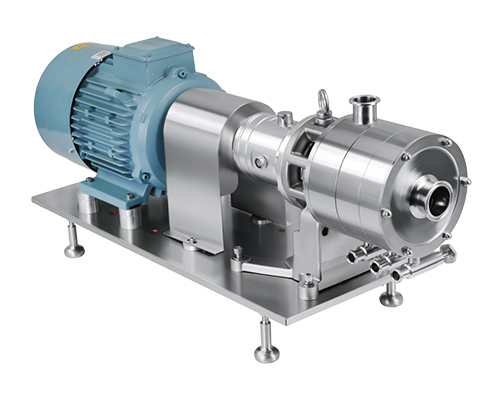

The pump is a hygienic design side slot, self-priming pump for the food processing, pharmaceutical and chemical industries.

Designed for pumping materials containing air or gas, it can be used in negative suction with preferential suction and filtration equipment. It also can be used in wine, oil, syrup, volatiles, such as alcohol, acetone tanks and other solvents, or other materials with a temperature near the boiling point. However. The main purpose of this pump is for CIP recycling

Maximum flow rate Max Flow rate: 40m3/h

Maximum head Max Head: 42 H/M

Maximum suction Max suction: 8 / M

Temperature: -20 ° C to 130 ° C Temperature: -20 ° C to 130 ° C

Power power :1.5-15KW

Material Material: 304 /316L, 1.431/1.4404, ASME BPE 316L, 1.4435 NB2 Fe≤0.5%

Surface treatment: ≤ Ra0.8μm, ≤ Ra0.6μm, ≤ Ra0.4μm

Machine seal: single machine seal, double machine seal

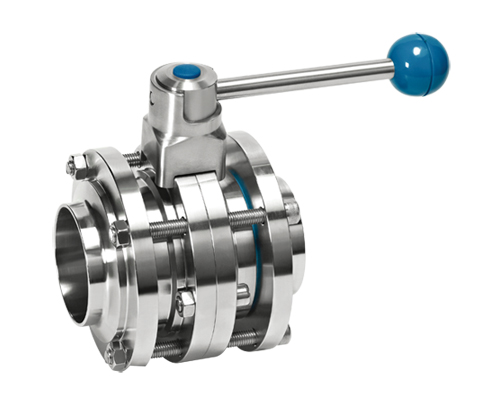

Inlet/Outlet Connection: Thread, Clamp, Flange, Aseptic Flange

Certification: 3-A-02-10 (N.O.1579); MD/06/42-EC (N.O.70521616101-00); FDA 177.2600; USP CLASS-II; EG/VO1935/2004;