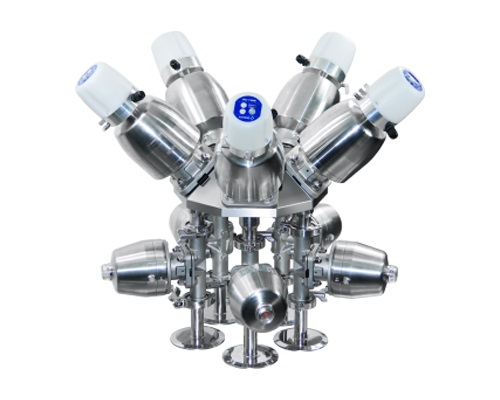

Tank Bottom Radial Diaphragm Valve

●Mainly used in pharmaceutical, biotech, health care, cosmetic and food industries, etc.

●In the pharmaceutical industry, valves can be used as process control valve, dosing valve, sampling valve and aseptic drain valve, etc.

●In the food industry, valves are often used as guide device, such as sampling valve, dosing valve (For example adding CO2/Nitrogen to beer, add seasoning to drink). Radial diaphragm valve are mainly manually and pneumatically operated with inside body finished Ra≤0.5 um, in order to meet the requirements of biopharmaceutical industry.

● Size: 3/4 "-2.5", DN20-DN65

● Working Temperature: -10 ℃ to 120 ℃ (EPDM/ Silcon)

● Maximum Pressure: 6bar

● Operation: Manual/ Pneumatic interchangeable

● Actuator Pressure: 5bar-6bar

● Outlet Connection: Weld, Clamp, Special interface

● New diaphragm design

● Maintenance is simple, safe, easy to operate

● Self-emptying

● Minimize dead angle

● Excellent value KV

● CIP/ SIP sterilization and cleaning