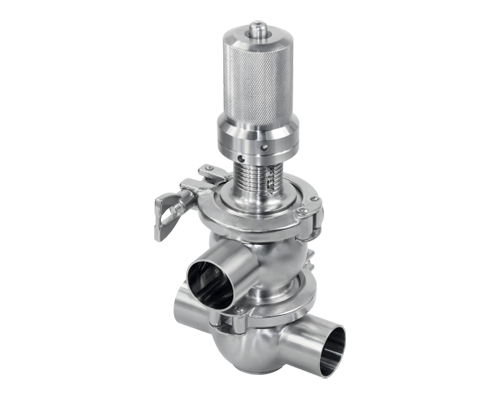

Application

◎The safety valve is used to protect the flow pressure safety through pipes, pumps, accessories, pools, etc.

◎With sanitary and safe design, it's avoid operation danger and equipment failure caused by exceed pressure.

◎With sanitary design and completely material of stainless steel, the valves is the best choice for protection of equipment in diary, food, beverage, pharmaceutical and fine chemical industries.

Operating Principles

Manual fast row safety valve features: you can open the valve manually, the spot cleaning (used together with the pump channel) can allow the fluid to pass through

◎Under normal operating conditions, the valve remains closed.

◎The specific pressure is set by adjusting the spring pressure nut.

◎When the pressure in the pipes is exceed the specific pressure, the valve will open automatically to make the liquid pass over,so that pressure in the pipeline is reduced.

◎The valve can be operated with handle . When the handle remains open on the operation spot, the detergent can flow though the flow valves.

◆Size:1"-4",DN25-DN100

◆KV Value:8.5-180m3/h

◆Max. Temperature:130℃(EPDM)/266℉

◆Set Pressure:(0-3bar/0-6bar/6-10bar)

◆Material:304/316L

◆Certification: safety valve manufacturing license for special

-1.png)