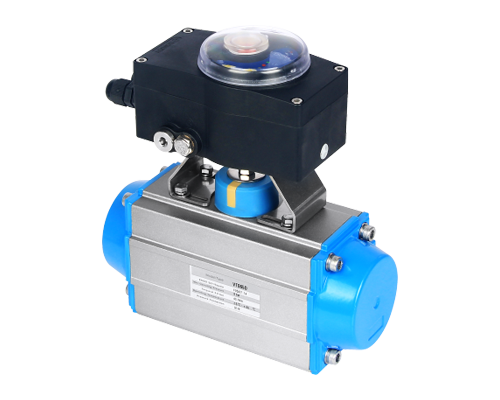

C-TOP-1881 is a straight-stroke pneumatic valve control unit designed for valve process control. It is compatibled with most PLC (programmable logic controller) automation systems with digital communication or bus communication (AS- I BUS). Including position feedback output, two-stage LED light display, anti-leak function, valve opening and closing control, etc., used to control all types of process valves. It can be mounted on a variety of pneumatic valves, such as pneumatic butterfly valves, ball valves, diaphragm valves, angle seat valves, globe valves, reversing valves, etc.…..

Control input: PNP DC 24V

Feedback Output : PNP DC 24V

Power supply : DC24V ± 10%

Bus communication : AS-I-BUS

Accuracy: Repeat positioning accuracy ≤ 0.2%;

Setting: One-button auto-tuning function

Operating mode: automatic & manual

Leak prevention diagnostic function

Display: two-segment lamp color

Open: green / red

Close: red / green

Travel range: 0-60mm/0-30mm